Designer of Industrial Solutions for Aeronautics and Space

Particularly aware of these requirements for many years, Acim Jouanin will be able to assist and advise you in searching solutions, making its engineering resources available to support you from the development phase to the final completion of the equipment.

- Accueil

- Activity areas

- Aeronautics

Heat Shrinking of Parts

Shrinking, a technique consisting of assembling two mechanical parts by means of a tight fit, is a “must” in the aeronautics industry.

Playing on the phenomenon of expansion of metals, the outer element called “hoop” is heated in order to introduce the inner part, called “hoop part” and allow when the assembly cools, to make one and the other united.

We have developed and implemented technical solutions, based on heating and control elements, intended for the fitting of landing gear parts, reactors (CFM56, LEAP, etc.) rocket tanks (Ariane 5) or even bearings.

Our knowledge of temperature control allows us to obtain regular and homogeneous heating, achieving the best results, without the risk of weakening the materials.

We will use this expertise to develop these heating elements in your production lines and workshops.

To guarantee the quality of the shrinking of your parts, do not hesitate to call on our electrothermal engineers.

Aluminum Processing

For this essential metal in the aeronautics industry, Acim Jouanin designs and develops electric heating solutions from the production of aluminium “slugs” (metal cylinder intended for hot shaping) to the extrusion dies for leading edge of airplane wings or helicopter blades.

In this kind of application, Acim Jouanin’s engineering services are able to offer, not only the heating and control of the extrusion dies, through which the aluminum slugs will be pressed, but also the furnace necessary for preheating the material, thus guaranteeing the quality of the finished product.

Do not hesitate to push the door of our Design Office with your specifications to discuss with our specialists.

Shaping of Composites Materials

Aeronautics gives room and space to composite materials, replacing metal parts. Much lighter and more resistant, they reduce the weight of aircraft, drastically reducing fuel consumption.

Consisting of several layers of carbon fibers, they must be heated to be able to be shaped and achieve to the desired technical characteristics.

Each kind of composite has its specific heating cycle, alternating preheating, ramp controlled or not, stabilisation segments…

As an electric heating elements specialist, the warming up of composites is fully within our field of expertise. Several well-known manufacturers have already trusted us to equip their forming and draping molds with composite parts requiring great temperature uniformity.

Polymerization of Coatings

Polymerization is a chemical reaction during which bonds are established, making it possible to solidify and increase the properties of the material. This phenomenon can occur naturally for certain compounds, but the addition of heat accelerates and reinforces it.

The application of resins, glues or paints requires baking in order to obtain complete polymerization. It must be precise and homogeneous, following heating cycles with optimized temperature rise and specific cooling profiles.

Acim Jouanin is proud of several achievements of this type in the aeronautical field, in particular for a player in this sector who wanted to polymerize first a primer then a finishing paint on engine parts. The technical solution adopted was based on a mobile infrared heating system composed of several zones making possible the heating of a targeted or larger part of the item. The temperature control of each zone is ensured by an IR pyrometer linked to a programmer temperature controller, installed together in an electrical cabinet.

Infrared ramp, heat treatment furnaces… we will be able to develop the solution adapted to your process.

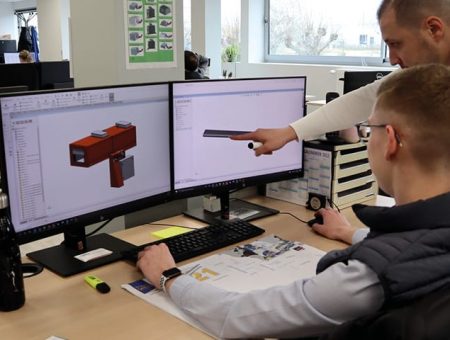

Customised Advices and Engineering with Acim Jouanin

Our know-how is at your disposal to optimize all steps of your production. Our role is to bring you the targeted temperature at a precise location, in a regular and homogeneous base.

We are able to offer you different solutions to achieve this. Call on our engineers from the beginning of the pre-study phase of your project to define the solution best suited to your way of working, your production, your requirements and your needs.

Engineers at the service of other engineers, we know your problems and will be able to help you solve them with the right tools, the right conditions, the right temperatures and the best control.