Theoretical formulas

Thermal

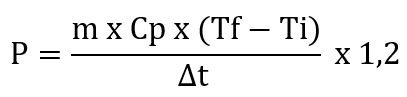

Heating of static products without change of state:

.

Determination of the power required for heating static products, which do not change state when the temperature rises:

- Legend:

- P: power (W)

- m: mass to be heated (kg)

- Cpm: specific heat (J/kg.K)

- Ti: initial temperature (°C)

- Tf: final temperature (°C)

- Δt: temperature rise time (sec)

- 1.2: safety factor

.

- Downloadable calculation in excel

.

This calculation makes it possible to estimate the theoretical power to be installed to heat the material alone. The parameters taken into account do not take into account the thermal losses of the installation.

.

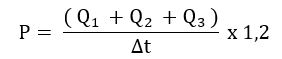

Heating of static products with change of state:

.

Determination of the power required for heating static products changing state during the rise in temperature:

- Energy requirment to heat the product to the state change temperature:

- Amount of heat required to obtain a change of state:

- Amount of heat to heat the product to its final temperature:

.

- Total power:

- Legend:

- Q: amount of heat (J)

- m: mass to be heated (kg)

- Cpmf: average specific heat, between the initial temperature and the state of change temperature (J/kg.K)

- Ti: initial temperature (°C)

- Tc: temperature at change of state (°C)

- Lf: Latent heat of fusion (J/kg)

- Cpmi: average specific heat, between the change of state temperature and the final temperature (J/kg.K)

- Tf: final temperature (°C)

- Δt: Required warm up time to reach the final temperature (sec)

- 1.2: safety factor

- P: power to be installed (W)

.

- Downloadable calculation in excel

- .

This calculation makes it possible to estimate the theoretical power to be installed to heat the material alone. The parameters taken into account do not take into account the thermal losses of the installation.

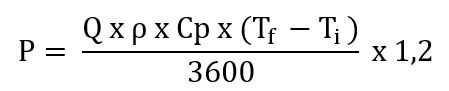

Heating of products in circulation, without change of state:

Determination of the power required for heating liquids in circulation, which do not change state when the temperature rises:

- Legend:

- P: power (W)

- Q: flow (m3/h)

- ρ: density (kg/m3)

- Cp: specific heat (J/kg.K)

- Ti: initial temperature (°C)

- Tf: final temperature (°C)

- 1.2: safety factor

.

- Downloadable calculation in excel

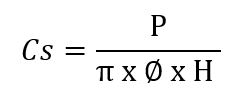

Determination of power density on a cylindrical surface:

.

This formula can be adapted to collar-type resistors, cartridges, shielded elements, etc.

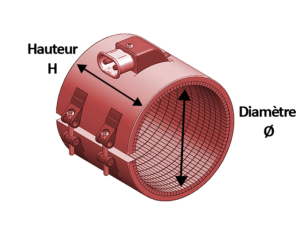

Collars:

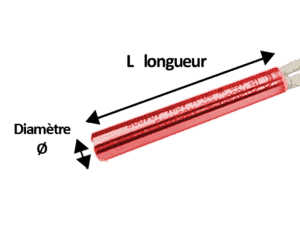

Cartridges:

Shielded elements: DIAGRAM

For flat surface resistors

Electric

Calculation of power, intensity and ohmic value:

Equations usable in single-phase alternating current or in direct current, for ohmic resistors

- Calculations

- U = Re x I ⇔ Re = U / I ⇔ I = U / Re

- P = U x I ⇔ U = P / I ⇔ I = P / U

- P = Re x I² ⇔ Re = P / I² ⇔ I = √(P / Re)

- P = U² / Re ⇔ Re = U² / P ⇔ U = √(P x Re)

- Legend:

U: voltage (V) // Re: equivalent resistance (Ω) // I: current (A) // P: power (W)

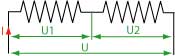

Coupling resistors in series:

- Calculations :

- Re = R1 + R2 + …

- I = I1 = I2 = …

- U = U1 + U2 + …

- Legend:

U: voltage (V) // Re: equivalent resistance (Ω) // I: current (A)

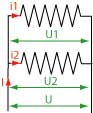

Coupling resistors in parallel:

- Calculations :

- 1/Re = 1/R1 + 1/R2 + …

- I = i1 + i2 + …

- U = U1 = U2 =…

- Legend:

U: voltage (V) // Re: equivalent resistance (Ω) // I: current (A)

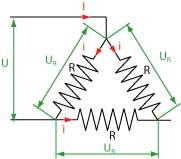

In the cases below, we will base ourselves on cases with 3 resistors of identical ohmic value, so that each line is balanced.

Triangle connection:

- Calculations :

- I = ix √3

- U = Ur

- Pglobal = (3 x U²) / R = √3 x U x I = 3 x U xi

- Legend:

U: voltage in the line (V) // Ur: voltage by resistance (V)

R: ohmic value per resistor (Ω)

I: current in the line (A) // i: current by resistance (A)

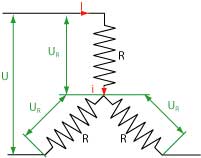

Star connection

In the case of 3 resistors of identical ohmic value.

- Calculations :

- I = i

- U = Ur x √3

- Pglobal = U² / R = (3 x Ur²) / R = √3 x U x I

- Legend:

U: voltage in the line (V) // Ur: voltage by resistance (V)

R: ohmic value per resistor (Ω)

I: current in the line (A) // i: current by resistance (A)

Unit conversion

Kelvin………… K = °C + 273

Celsius………. °C = K – 273

1 joule = 0.24 calories

1 calorie = 4.18 joules

Joules: J

calories: calories

1 liter = 1 dm3 = 0.001 m3

1m3 = 1000 liters

1 cal/kg. K = 4.18 J/ kg.K

1 J/ kg.K = 0.238 cal/kg.K

Thermocouples and probes

Standard colors of thermocouple cables

| Couple | International NF EN IEC 60584-3 | France NF C 42-324 | England BS 1843 | Germany DIN 43714 | Japan JISC1610 | USA ANSI/MC96.1 | |

| J | Pole+ | ||||||

| Pole- | |||||||

| K | Pole+ | ||||||

| Pole- | |||||||

.

Table of Electromotive Force FEM of thermocouples J

According to standard NF EN IEC 60584-1

Alloy: Positive pole = iron /// Negative pole = copper – nickel

Theoretical operating temperature range: -200°C to + 750°C

FEM, for a cold junction (reference point) at 0°C.

EMF in millivots, temperature in celsius.

| °C | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 |

| 0 | 0,000 | 0,507 | 1,019 | 1,536 | 2,058 | 2,585 | 3,115 | 3,649 | 4,186 | 4,725 |

| 100 | 5,268 | 5,812 | 6,359 | 6,907 | 7,457 | 8,008 | 8,560 | 9,113 | 9,667 | 10,222 |

| 200 | 10,777 | 11,332 | 11,887 | 12,442 | 12,998 | 13,553 | 14,108 | 14,663 | 15,217 | 15,771 |

| 300 | 16,325 | 16,879 | 17,432 | 17,984 | 18,537 | 19,089 | 19,640 | 20,192 | 20,743 | 21,295 |

| 400 | 21,846 | 22,397 | 22,949 | 23,501 | 24,054 | 24,607 | 25,161 | 25,716 | 26,272 | 26,829 |

| 500 | 27,388 | 27,949 | 28,511 | 29,075 | 29,642 | 30,210 | 30,782 | 31,356 | 31,933 | 32,513 |

| 600 | 33,096 | 33,683 | 34,273 | 34,867 | 35,464 | 36,066 | 36,671 | 37,280 | 37,893 | 38,510 |

| 700 | 39,130 | 39,754 | 40,382 | 41,013 | 41,647 | 42,283 |

.

Table of EMF Electromotive Force of K thermocouples

According to standard NF EN IEC 60584-1

Alloy: Positive pole = nickel-chrome /// Negative pole = nickel-aluminum

Theoretical operating temperature range: -200°C to + 1100°C

FEM, for a cold junction (reference point) at 0°C.

EMF in millivots, temperature in celsius

°C | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 |

| 0 | 0,000 | 0,397 | 0,790 | 1,203 | 1,611 | 2,022 | 2,436 | 2,850 | 3,266 | 3,681 |

| 100 | 4,095 | 4,508 | 4,919 | 5,327 | 5,733 | 6,137 | 6,539 | 6,939 | 7,338 | 7,737 |

| 200 | 8,137 | 8,537 | 8,938 | 9,341 | 9,745 | 10,151 | 10,560 | 10,969 | 11,381 | 11,793 |

| 300 | 12,207 | 12,623 | 13,039 | 13,456 | 13,874 | 14,292 | 14,712 | 15,132 | 15,552 | 15,974 |

| 400 | 16,395 | 16,818 | 17,241 | 17,664 | 18,088 | 18,513 | 18,938 | 19,363 | 19,788 | 20,214 |

| 500 | 20,640 | 21,066 | 21,493 | 21,919 | 22,346 | 22,772 | 23,198 | 23,624 | 24,050 | 24,476 |

| 600 | 24,902 | 25,327 | 25,751 | 26,176 | 26,599 | 27,022 | 27,445 | 27,867 | 28,288 | 28,709 |

700 | 29,128 | 29,547 | 29,965 | 30,383 | 30,799 | 31,214 | 31,629 | 32,042 | 32,453 | 32,866 |

| 800 | 33,277 | 33,686 | 34,095 | 34,502 | 34,909 | 35,314 | 35,718 | 36,121 | 36,524 | 36,925 |

| 900 | 37,325 | 37,724 | 38,122 | 38,519 | 38,915 | 39,310 | 39,703 | 40,096 | 40,488 | 40,879 |

| 1000 | 41,269 | 41,657 | 42,045 | 42,432 | 42,817 | 43,202 | 43,585 | 43,968 | 44,349 | 44,729 |

| 1100 | 45.108 |

Table of the ohmic value of PT100 probes, depending on the temperature:

According to standard NF EN IEC 60751

°C

|

0

|

10

|

20

|

30

|

40

|

50

|

60

|

70

|

80

|

90

|

0

|

100,00

|

103,90

|

107,79

|

111,67

|

115,54

|

119,40

|

123,24

|

127,07

|

130,89

|

134,70

|

100

|

138,50

|

142,28

|

146,06

|

149,82

|

153,57

|

157,32

|

161,04

|

164,76

|

168,47

|

172,16

|

200

|

175,84

|

179,51

|

183,17

|

186,82

|

190,46

|

194,08

|

197,70

|

201,30

|

204,88

|

208,46

|

300

|

212,03

|

215,58

|

219,13

|

222,66

|

226,18

|

229,69

|

233,19

|

236,67

|

240,15

|

243,61

|

400

|

247,06

|

250,50

|

253,93

|

257,31

|

260,75

|

264,14

|

267,52

| 270,89 |

274,25

|

277,60

|

500

|

280,93

|

284,26

|

287,57

|

290,87

|

294,16

|

297,43

|

300,70

|

303,95

|

307,20

|

310,43

|

600

| 313,65 |

316,86

|

320,05

|

323,24

|

326,41

|

329,57

|

332,72

|

335,86

|

338,99

|

342,10

|

700

|

345,21

|

348,30

|

351,38

|

354,45

|

357,51

|

360,55

|

363,59

|

366,61

|

369,62

|

372,62

|

800

|

375,61

|

378,59

|

381,55

|

384,50

|

387,45

|

390,38

|

°C

|

0

|

10

|

20

|

30

|

40

|

50

|

60

|

70

|

80

|

90

|

0

|

100,00

|

103,90

|

107,79

|

111,67

|

115,54

|

119,40

|

123,24

|

127,07

|

130,89

|

134,70

|

100

|

138,50

|

142,28

|

146,06

|

149,82

|

153,57

|

157,32

|

161,04

|

164,76

|

168,47

|

172,16

|

200

|

175,84

|

179,51

|

183,17

|

186,82

|

190,46

|

194,08

|

197,70

|

201,30

|

204,88

|

208,46

|

300

|

212,03

|

215,58

|

219,13

|

222,66

|

226,18

|

229,69

|

233,19

|

236,67

|

240,15

|

243,61

|

400

|

247,06

|

250,50

|

253,93

|

257,31

|

260,75

|

264,14

|

267,52

| 270,89 |

274,25

|

277,60

|

500

|

280,93

|

284,26

|

287,57

|

290,87

|

294,16

|

297,43

|

300,70

|

303,95

|

307,20

|

310,43

|

600

| 313,65 |

316,86

|

320,05

|

323,24

|

326,41

|

329,57

|

332,72

|

335,86

|

338,99

|

342,10

|

700

|

345,21

|

348,30

|

351,38

|

354,45

|

357,51

|

360,55

|

363,59

|

366,61

|

369,62

|

372,62

|

800

|

375,61

|

378,59

|

381,55

|

384,50

|

387,45

|

390,38

|