Electric Heating Tunnels

and Infrared Panels

Our expertise in thermal, electricity, process control, automation and mechanics allow us to offer global heating solutions adapted to your process.

Offering decades of experience, our thermal engineers design heating tunnels and infrared plates to guarantee uniform heating of your itemss.

- Accueil

- Our product range

- Electric Heating Tunnels and Infrared Panel

Electric heating tunnels and process radiant heaters

Our expertise in thermal, electricity, process control, automation and mechanics allow us to offer global heating solutions adapted to your process.

Offeringdecades of experience, our thermal engineers design heating tunnels and infrared plates to guarantee uniform heating of your items.

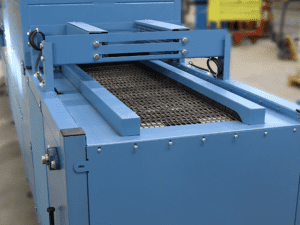

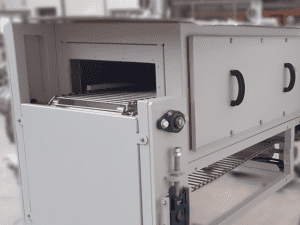

Heating Tunnels

Our electric heating tunnels equipped with conveyors or conveyor belts are specifically designed to heat your parts continuously , according to a defined running speed.

The applications are multiple ( cooking , drying , heating , etc.) and present in many sectors of activity such as the food industry, glassware, textiles, automotive, etc.

Manufactured in one piece or modular form, the tunnels can be structured into multiple heating zones in order to respect the cooking or treatment profiles defined by your process:

- Heating by hot air in forced convection,

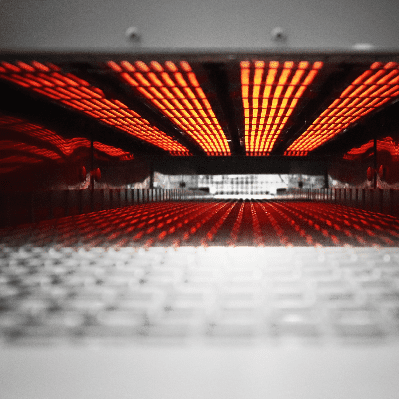

- Heating by infrared emitters adapted to the product and the type of treatment desired (ceramic emitters, infrared lamps, radiant ceramic plates, shielded elements)

- Cooling area

Custom manufacturing allows the structure of the tunnel to be adapted according to the characteristics of the product to be heated (dimensions, material, etc.), thus allowing its integration into your production line.

According to customer recommendations, the external metal wall can be in painted steel or stainless steel according to customer recommendations.

The thermal insulation of the various compartments, made of ceramic fiber and high-density rock wool, makes it possible to concentrate the heating flows towards the part to be heated, thus limiting losses.

The products to be treated move forward in the tunnel thanks to a belt adapted to the mass and the shape to be moved (mesh belt, strip belt, etc.)

The electricity supply and temperature regulation of the tunnel are provided by an on-board or remote electrical cabinet, depending on your needs. Temperature measurements can be made by PT100 probes, thermocouples or infrared pyrometers.

Heating zones are controlled by one or more PID control loops, simple or programmable , with measurement copying or communication with a PLC, then relayed on touch screens for more user-friendly viewing. Our electrical cabinets are custom made at our Normandy site of Evreux (27), as the rest of our production.

Our design office is at your disposal to assist you in the design and production of heating tunnels meeting your technical requirements. Do not hesitate to contact us.

Infrared Panels

The emitters and infrared lamps allow the heating of the material without contact, while being freed from the atmosphere, thus limiting the thermal losses . Infrared allows rapid transmission of energy to targeted areas.

In addition to our range of standard transmitters (link ), we design and manufacture technical solutions, made to measure, allowing these transmitters to be integrated into complete installations.

Infrared panels make it possible to answer to many applications such as the baking of paint by allowing its polymerization, the preheating of thermoplastic composites before shaping, the drying of aqueous solutions, etc.

Our wide range of infrared emitters allows you to choose the model best suited to your process , depending on your thermal requirements, product characteristics (dimensions, material, color, condition, etc.) and the treatment to be carried out.

Ceramic emitters, quartz elemnts, short infrared lamps, radiant ceramic plates, tubular elements… We invite you to contact us to define your needs together.

As a manufacturer, we can make panels of various shapes that can be installed vertically or horizontally (vault, crown, etc.)

We are also able to ensure the temperature control of these panels, by infrared pyrometers allowing precise measurement of the treated product.

Do not hesitate to consult us.