Ceramic strip heaters

Ceramic strip heaters can heat up to around 600 ° C, solids by direct heating, as well as fluids and gases by indirect heating. Their design uses 2 different technologies:

Radiant ceramic strip heaters (PCTR) consist of a heating element isolated by flat open ceramics. They are intended for heating scroll tunnels or furnaces.

Rigid ceramic strip heaters (PCR) consist of a heating element dielectrically insulated by ceramic modules, protected by a metal frame. They are used for heating molds.

- Accueil

- Our product range

- Strip heaters

- Ceramic strip heaters

Ceramic strip heaters

Ceramic strip heaters can heat up to around 600 ° C, solids by direct heating, as well as fluids and gases by indirect heating. Their design uses 2 different technologies:

Radiant ceramic strip heaters (PCTR) consist of a heating element isolated by flat open ceramics. They are intended for heating scroll tunnels or furnaces.

Rigid ceramic strip heaters (PCR) consist of a heating element dielectrically insulated by ceramic modules, protected by a metal frame. They are used for heating molds.

- Maximum temperature of use 600 ° C , according to the conditions of use

- Max load: 7 W / cm² , depending on the conditions of use

Uniquement disponibles sur mesure, nos résistances plates céramiques sont réalisées selon votre cahier des charges et peuvent être personnalisées (connectiques, serrages…) et équipées d’accessoires, en fonction de leur température d’utilisation.

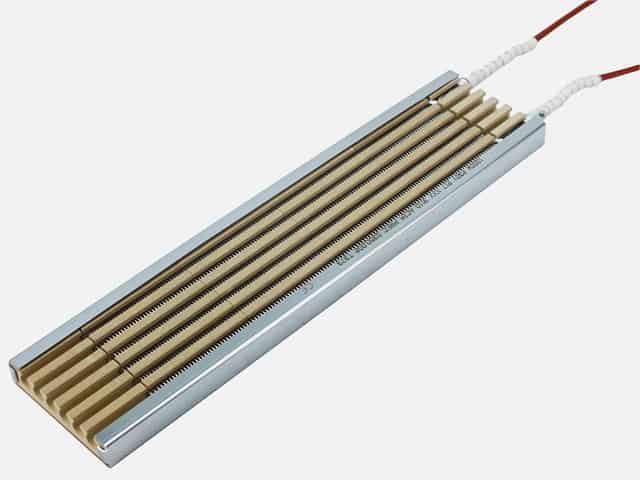

Radiant Ceramic Strip Heaters (PCTR)

Radiant ceramic strip heaters are particularly reactive and allow immediate radiation to the surface to be heated.

- Heating wire in nickel chrome 80/20 .

- Electrical insulation by flat rectangular ceramics, 80 mm wide .

- Connection by high temperature siliconized glass silk insulated wires, protected by ceramic beads.

- Metal frame stiffening the assembly and allowing it to be fixed.

- Fixing by brackets fixed on the metal frame.

Ceramic strip heaters are made to measure , according to your specifications. Below is a summary of the main technical data:

-

- Width: 83 mm +/- 2 mm

- Length: 90 to 2000 mm +/- 2 mm.

Including non-heating minimum lengths of 30 mm at each end. - Thickness: 18mm

- Metal frame: stainless steel as standard. Optional Inconel for very high temperatures

- Connection by high temperature nickel wires insulated with siliconized glass silk, protected by 100 mm of ceramic beads

- Voltage: 230 V or 400 V, other voltage on request.

Single phase: 2 or 4 wire output / Three phase: 6 wire - Stainless steel brackets

.

- Example of specific realization: Remote connection (addition of a larger non-heating zone between the connection and the heating zone)

.

This list is not exhaustive : Fill in the definition form and contact us

Characteristics applicable to ceramic strip heaters :

- Power tolerance: -10% / +5%

- Our products comply with Directives 2014/35/EU (Low voltage / LVD), 2014/30/EU Electromagnetic Compatibility (EMC) and 2011/65/EU ( RoHs ) (+2015/863/EU modifying appendix II of Directive 2011/65/EU)

- Complies with REACH regulations

Products associated with ceramic strip heaters, to power them electrically and regulate their temperature:

- Cables (power supply, thermocouples) & accessories (sockets, connectors ….)

- Temperature sensors (thermocouples, PT100 probes)

- Temperature control (electrical boxes, regulators, thermostats, etc.)

Ceramic strip heaters:

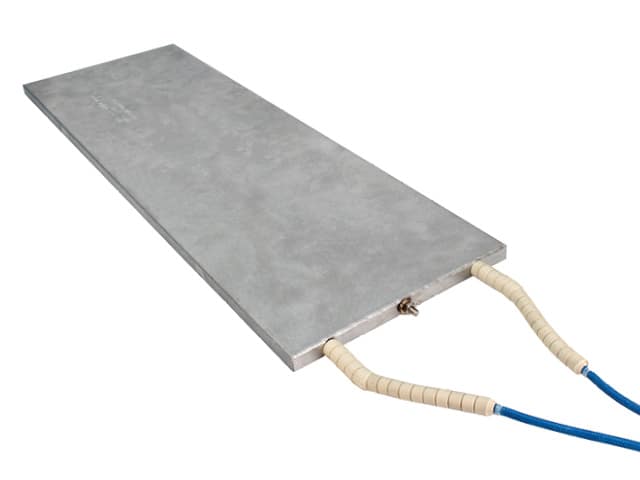

Rigid Ceramic Strip Heaters (PCR)

Rigid ceramic strip heaters are intended for high temperature heating, by conduction, of vessel walls or trays.

This technology, flexible thanks to the soapstone elements, allows the heating of large dimensions.

- Heating wire in nickel chrome 80/20 .

- Electrical insulation by soapstone elements.

- Protection by an enveloping sheet.

- Connection by high temperature wires protected by ceramic beads, terminals or cable outlet under the cover.

The rigid ceramic strip heaters are made to measure , according to your specifications. Below is a summary of the main technical data:

- Width: 15 to 250 mm . For bigger dimensions, please consult us.

- Length: 80 to 1500 mm +/- 2 mm.

- Thickness: 11.5mm

- Enveloping sheet in aluminized sheet, stainless steel or inconel depending on the temperature of use.

- Connection by:

- Nickel wire insulated with siliconized glass silk protected by ceramic beads, on the top of the resistance or in the thickness

- Cable under cover, on top of resistance

- Threaded terminals M4 to M6, depending on the intensity.

- Voltage: 230 V single phase, as standard. Other voltage on request.

.

This list is not exhaustive : Fill in the definition form and consult us !

Characteristics applicable to rigid ceramic strip heaters :

- Power tolerance: -10% / +5%

- Our products bear the CE marking because they comply with Directives 2014/35/EU (Low voltage / LVD), 2014/30/EU Electromagnetic Compatibility (EMC) and 2011/65/EU ( RoHs ) (+2015/863/EU modifying the Annex II of Directive 2011/65/EU)

- Complies with REACH regulations

Products associated with rigid ceramic strip heaters, to power them electrically and regulate their temperature:

- Cables (power supply, thermocouples) & accessories (sockets, connectors ….)

- Temperature sensors (thermocouples, PT100 probes)

- Temperature control (electrical boxes, regulators, thermostats, etc.)

Rigid ceramic strip heaters