Special Immersion Heaters

The main advantages of special Acim Jouanin immersion heaters are related to their ability to be extracted from a bath without draining and to resist corrosion from aggressive products (acid, etc.).

To achieve this, different heating elements technologies are available:

Ceramic Core Heaters, protected by a thermowell, are commonly used for heating special baths or water heaters.

Removable Immersion Heater , used at the bottom or at the edge of the tank, allow the heating of open baths and are in direct contact with the fluid to be heated.

The coating of Teflon® Immersion Heaters allows the direct heating of corrosive or acidic baths. Small in size, they are mainly installed on the edge or at the base of the tank.

- Accueil

- Our product range

- Immersion Heaters

- Special Immersion heaters

Special Immersion heaters

The main advantages of special Acim Jouanin immersion heaters are related to their ability to be extracted from a bath without draining and to resist corrosion from aggressive products (acid, etc.).

To achieve this, different heating elements technologies are available:

Ceramic Core Heaters, protected by a thermowell, are commonly used for heating special baths or water heaters.

Movable immersion heater , used at the base or at the edge of the tank, allow the heating of open baths and are in direct contact with the fluid to be heated.

The coating of Teflon® Immersion Heaters allows the direct heating of corrosive or acidic baths. Small in size, they are mainly installed on the edge or at the base of the tank.

Ceramic Core Elements (RSB)

Used for heating fluids when they are protected by a thermowell, the ceramics core elements can also be used to heat solids.

This technology has many advantages:

– Manufacture of very long elements (up to 6 m), where the technology of tubular elements is more limited.

– Low surface load to protect “fragile” fluids (oils, acids, etc.).

– Better resistance to fouling of heating circuits (scale, tank base sludge, etc.)

Features :

- Assembly of steatite cylinders, inserted into each other called “barrels”, held together by a threaded rod, passing through their center.

- Coiled heating wire in 80/20 nickel-chrome passing through the lateral interstices of the barrels, allowing outward radiation.

- End of the heating element protected by a ceramic head, with a diameter slightly larger than that of the barrels. The head can be offset from the heating elemnt for high temperature applications.

- Connection by threaded terminals or by wires protected by ceramic beads.

.

The ceramic core elements can be the subject of special finishes:

- The heaters can be supplied with a thermowell, to be used as an immersion heater

Generally made of stainless steel and equipped with a fixing flange or a screw plug, it can be protected by a coating depending on the nature of the product being heated. - The heating elements can be fitted with a connection box, in polycarbonate or aluminium.

The cermic core elements are exclusively custom made, according to your specifications.

Below is a summary of the main technical data:

- Barrel diameter: 36, 46, 56 mm . Other dimensions on request

- Length under head (plunging length): 100 mm minimum, maximum length 6 m , according to feasibility study.

- Heating length: 50 mm minimum then in multiples of 50 mm .

- All ceramic core elements are equipped with a non-heating zone under the head to protect the connectors. However, this zone can be extended to preserve the connections, in particular for operation at high temperature.

- Voltage: 24 V to 440V , single-phase or three-phase.

.

These heater can be mounted vertically or horizontally (to be specified during your consultation)

To define your product, complete our definition form and contact us.

- Manufacturing according to standard EN 60335-1

- Wattage tolerance: + 5% -10%

- Heaters compliant with Reach , Rohs and CE regulations

The use of ceramic core elements requires the installation of associated products:

- Cables (electric, thermocouples) & accessories (sockets, connectors, etc.)

- Temperature sensors (thermocouples, PT100 probes)

- Temperature regulation : electrical boxes, temperature controllers, thermostats …

Downloadable sheets :

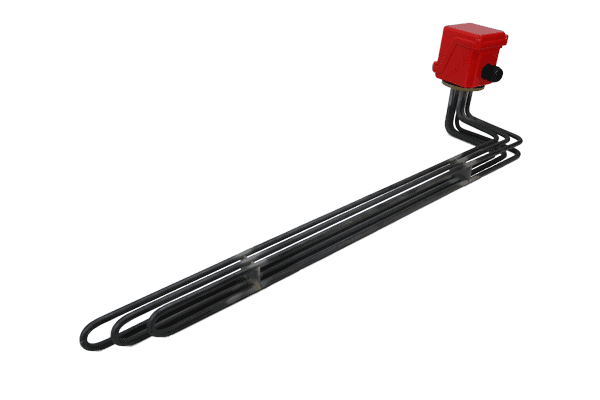

Removable Immersion Heaters

Removable immersion heaterallow the heating of open baths and are in direct contact with the fluid to be heated.

They guarantee easy maintenance without emptying, simplified cleaning and facilitate the changing of containers.

Exclusively custom made, the removable immersion heater are adapted to the configuration of the tank or bath, depending on the level of liquid contained and the space available. They can be positioned:

- Along the wall , releasing the entire surface of the tank,

- At the base of the tank , for better temperature uniformity,

- Inside containers (barrels, bowls, containers, IBC, etc.)

.

Features :

- Heating by tubular elements in direct contact with the fluid. The nature of the tubular element is chosen according to the nature of the liquid and the temperature of use (stainless steel, incoloy, etc.). In order to prevent possible corrosion, the tubular elements can be pickled and passivated.

For heating corrosive baths or for fluids that cannot withstand a high power density (W/cm²), the elements can be inserted in a sealed box protecting them and allowing a larger exchange surface. - According to the configurations, the heating elements can be protected by a riser tube.

- Adapted connection: cable output via a cable gland mounted on a handle, under a standard cover or under a sealed cover for the risk of projection, etc. Mostly, the connectors are remote from the tank to avoid any contact with the heated fluid.

- Fixing at the edge of the tank using a plate, flange, hooks, etc.

.

Removable immersion heater can be equipped with accessories such as temperature sensors or thermostats.

Note that it is necessary to provide safety to all immersion heaters by combining them with level detectors, the heating zone having to be permanently immersed in the fluid .

To help you define your product, contact us!

- Manufacturing according to standard EN 60335-1

- Wattage tolerance: + 5% -10%

- Heating elements comply with Reach , Rohs and CE regulations

The use of removable immersion heater requires the installation of associated products:

- Cables (electric, thermocouples) & accessories (sockets, connectors, etc.)

- Temperature sensors (thermocouples, PT100)

- Temperature control : electrical boxes, temperature controllers, thermostats …

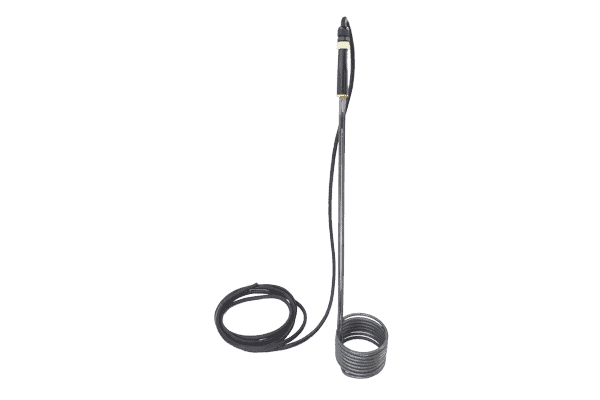

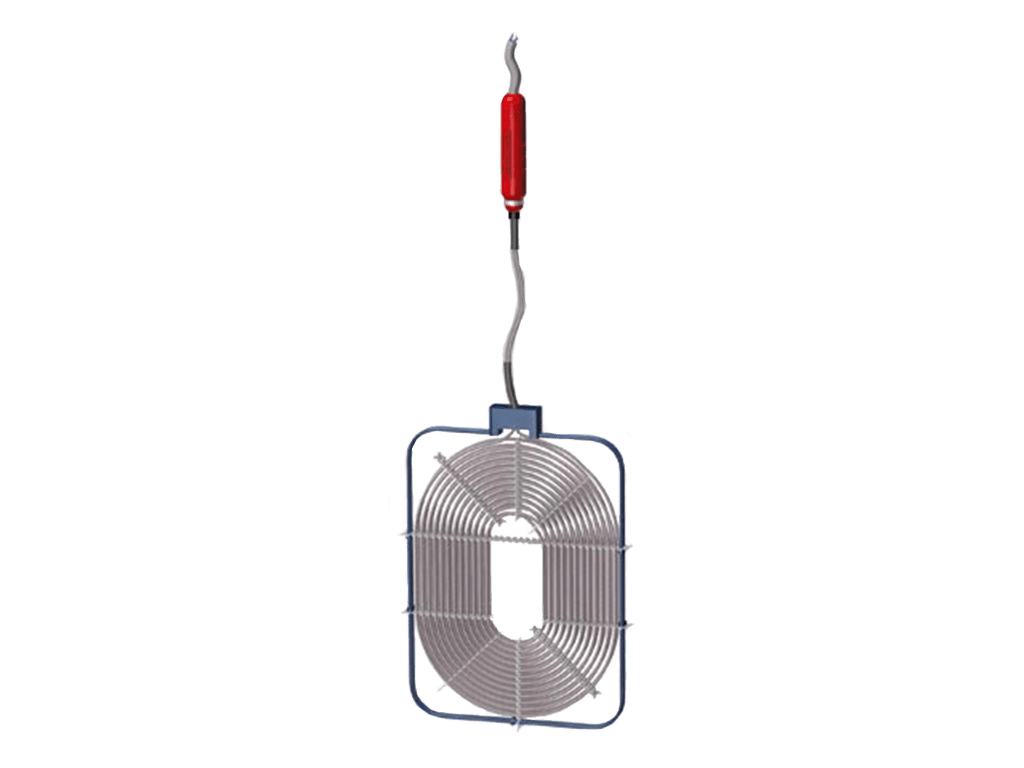

Teflon Immersion Heaters

Teflon ® immersion heaters, intended for heating corrosive baths up to 80°C.

These heating elements are available in different shapes, flat (rectangular) or cylindrical depending on the space available in the tank.

They can be arranged vertically along the wall or at the bottom of the tank, placed on feet.

- Heating elements consisting of a Teflon ® (FEP or PFA) insulated heating cable winding, with a power density of 1 W/cm² max .

The winding is held inside by spacers in PVDF, PP or FEP depending on the product being heated. - A structure, either metal coated with an insulator or in PP or PVDF plastic rod (for high powers), supports the heating part.

- Non-heating length protected by a braided PP (polypropylene) sheath, with black marks indicating the minimum and maximum immersion levels.

- IP64 connection sleeve, offset from the immersion heater by a non-heating zone.

- Power supply via flexible electric cable, length 1000 mm,

- Voltage from 110 V to 460 V, single-phase or three-phase depending on power.

Rectangular Immersion Heaters:

- Output in the width (output on the length, contact us)

- Width: 240 to 585 mm

- Length: 250 to 930 mm

- Power: 0.5 kW to 15 kW

.

. Cylindrical Immersion Heaters:

- Diameter: 85 to 125 mm

- Height: 185 to 1550 mm

- Power: 0.5 kW to 15 kW

- Electromagnetic Compatibility Directive (EMC) 2014/30/EU

- Low Voltage Equipment Directive 2014/35/EU

- EN 60519/1-2

- EN 60529, IP64

- Wattage tolerance: + 5% -10%

- Heating elements comply with Rohs and CE regulations

The use of Teflon ® immersion heaters requires the installation of associated products:

- Cables (electric, thermocouples) & accessories (sockets, connectors, etc.)

- Temperature sensors.

Caution: these sensors must be specifically adapted to the heating of corrosive baths and protected with Teflon ® . We offer 2 finishes, either flexible or rigid, in thermocouple J and in PT100 probe (2 or 3 wires). Do not hesitate to contact us. - Temperature control : electrical boxes, temperature controllers, thermostats …

Downloadable sheets :