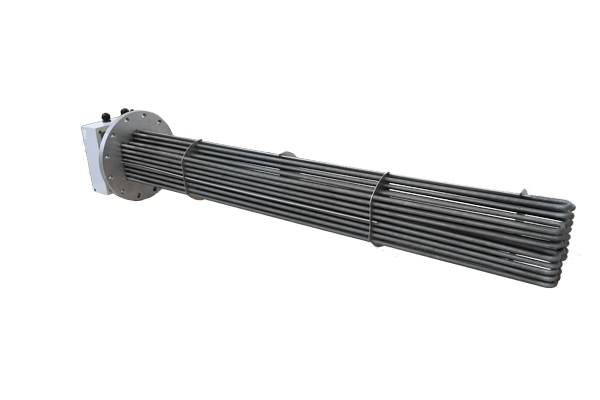

Flanged Immersion Heaters

Flanged immersion heaters are intended for heating static or circulating fluids (gas or liquid).

Consisting of multiple heating elements brazed or welded to a flange, they are the ideal solution for medium and high power heating.

Custom made, the different types of shielding (AISI, Incoloy, etc.) and flanges allow us to meet your most demanding specifications.

- Accueil

- Our product range

- Immersion Heaters

- Flanged Immersion Heaters

Flanged Immersion Heaters

Flanged immersion heaters are intended for heating static or circulating fluids (gas or liquid).

Consisting of multiple heating elements brazed or welded to a flange, they are the ideal solution for medium and high power heating.

Custom made, the different types of shielding (AISI, Incoloy, etc.) and flanges allow us to meet your most demanding specifications.

We design and manufacture flanged immersion heaters intended for applications such as heating in an ATEX environment, for gas and dust zones, with flanges DN 300 maxi.

Based on our experience, we will be able to provide you with the necessary advice to define the product you are looking for (type of heating element, specific load, type of connections, method of fixing, regulation, etc.).

Flanged Immersion Heaters

Custom made , flanged immersion heaters are adapted to the fluid and temperature of your application.

- Heating elements in steel , stainless steel or incoloy as required

- Closing of tubular heating elements by resin and welded or brazed on the flange.

- Wide range of flanges : DN.. PN.. , stamped sheet metal, lug, quick assembly (self-tightening), square shape…

- Connection by threaded or flat terminals, pins pre-wired by coupling bars.

- Connection cover adapted to the number of pins, molded in aluminum for low powers or in sheet metal for high powers.

.

Flanged immersion heaters can be fitted with accessories or special finishes:

- Safety device inserted in a glove finger (thermostat or probe)

- Remote connection box for high temperatures (above 110°C),

- Surface treatment by pickling passivation or specific coating (Halard, Teflon ® …),

- Tank bottom model …

Our flanged immersion heaters are exclusively custom made, according to your specifications, on our production site in Evreux .

They are specifically adapted to the product to be heated.

Below is a summary of the main features:

- Standard flange DN65 to DN400 , special flange according to specifications (square, triangular, etc.)

- Diameter of heating tubular elements: 6.5 to 16 mm

- Type of shielding: 309 stainless steel, 304 stainless steel, 321 stainless steel, 316 stainless steel, incoloy 800, incoloy 825,

- Overall heating pin length: 150 to 3500 mm , depending on tube diameters

- Manufacturing according to standard EN 60335-1

- Wattage tolerance: + 5% -10%

- Immersion heater certified CE

The use of immersion heaters requires the installation of associated products:

- Cables (electric, thermocouples) & accessories (sockets, connectors, etc.)

- Temperature sensors (thermocouples, PT100)

- Temperature control : electrical boxes, temperature controllers, thermostats …

Downloadable sheets :

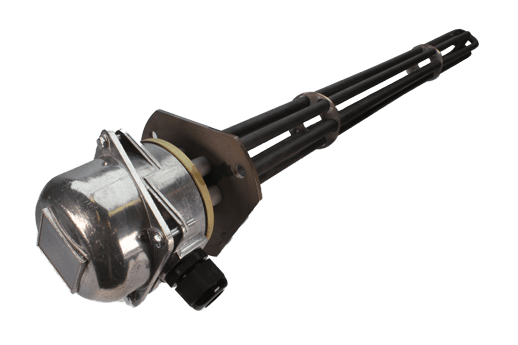

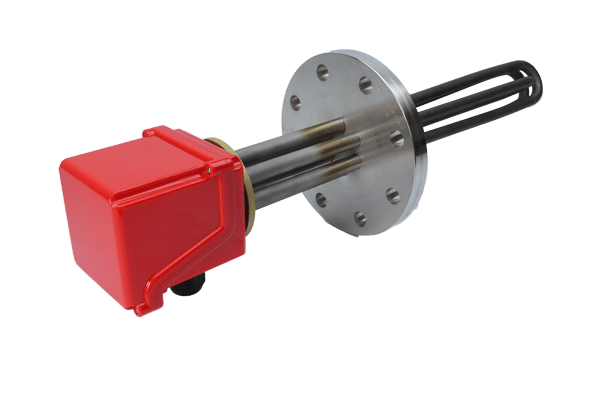

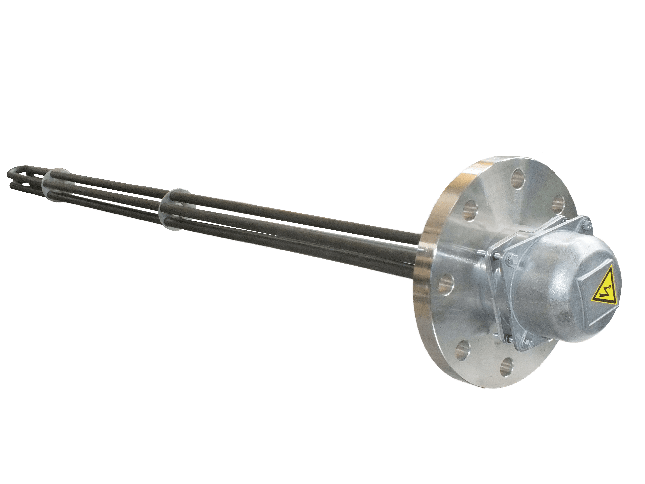

ATEX Flanged Immersion Heater

Intended for heating fluids in an ATEX and IECEX environment, these flanged immersion heaters are qualified to work in gas zones 1 and 2 and/or dust zones 21 and 22 at temperature classes T6 (85°C) to T1 (450°C) .

Exclusively custom made according to the product to be heated and the environment, our ATEX / IECEX approvals make it possible to meet the following conditions, according to the zones:

- Immersion heaters fitted with a DN80 Immersion heater DN100 flange:

- Zone 1 (gas), Zone 2 (gas), Zone 21 (dust) and Zone 22 (dust)

- Gas groups IIA, IIB, IIC; Dust groups IIIA, IIIB, IIIC;

- Ambient temperature: -20°C to +60°C;

- Temperature class (to be specified): T6 (85°C), T5 (100°C), T4 (135°C), T3 (200°C), T2 (300°C) or T1 (450°C).

- Certification: Ex II 2 GD – Ex d II C T6 to T1 Gb – Ex tb IIIC T85°C to T450°C Db

.

- Immersion heaters fitted with a DN100 Immersion heater DN300 flange:

- Zone 1 (gas), Zone 2 (gas);

- Gas groups IIA, IIB, IIC;

- Ambient temperature: -20°C to +40°C;

- Temperature class (to be specified): T6 (85°C), T5 (100°C), T4 (135°C), T3 (200°C), T2 (300°C) or T1 (450°C).

- Certification: Ex II 2 G – Ex d II C T6 to T1 Gb

.

- . For all other requests, contact us

space

Characteristics :

- Heating body made up of several tubular elements in steel, stainless steel or incoloy, depending on the application

- Fixing flange DN 80 to DN 300,

- Type “d” connection box (flameproof enclosure) in steel , IP 65 containing the connection terminals to the resistors, internal and external ground terminal. Number of ATEX IIC cable glands, adapted to the number of power stages and the section of the power cables.

- Immersion heater fitted with 2 thermal safety devices (probe, thermostat, etc.) whose sensitive parts are located in a sealed glove pocket near the heating elements. The devices can be connected in the connection box or in a remote box.

Our ATEX / IECEX flanged immersion heaters are custom made, according to your specifications, on our Evreux production site. They are specifically adapted to the product to be heated and to the environment (tank, area, etc.).

Below is a summary of the main technical data:

- The connection box is offset from the flange by 120 mm for class T3 to T6 models and by 220 mm for classes T1 and T2.

- The safeties can be of the bulb thermostat type, PT 100 probe, thermocouples (to be specified).

- Non-heating zone of 80 mm, under the flange. It is possible to increase this length if necessary.

- Maximum supply voltage: 750 V tri .

- Maximum power: 390 kW.

space

To define your product, complete our definition form and contact us

- Equipment meeting standards and directives : 2014/34/EU, EN 60079-0, EN 600079-1, IEC 60079-0, IEC 60079-1

.

- Immersion heaters fitted with a DN80toDN100 flange:

- Immersion heater heaters certified Ex d II C T6 to T1 Gb – Ex tb IIIC T85°C to T450°C Db,

- EC type examination certificate number: INERIS 06ATEX0046X

- IECEX conformity certificate: INE 14.0054X

- Immersion heater heaters certified Ex d II C T6 to T1 Gb – Ex tb IIIC T85°C to T450°C Db,

space

- Immersion heaters fitted with a DN100 to DN300 flange:

- Ex d II C T6 to T1 Gb Immersion heater

- EC type examination certificate number: INERIS 09ATEX0030X

- IECEX conformity certificate: INE 14.0053X

space

- Power tolerance: +5% / -10%

The use of ATEX screw- plug immersion heaters requires the installation of associated products that are also ATEX certified :

- ATEX sockets ;

- ATEX temperature sensors

Products available on request, please contact us.

.

In addition, we also offer articles intended for non-Atex zones:

- Cables (electric, thermocouples) & accessories (sockets, connectors, etc.)

- Temperature sensors (thermocouples, PT100)

- Temperature control : electrical boxes, temperature controllers, thermostats …

Downloadable sheets :