How to heat a solid?

Heat a solid can be done in two ways: direct or indirect . In direct mode, the heating element is in contact with the part. In indirect mode, it acts at a distance.

These techniques can be applied to drying, heat sealing, baking…

Acim Jouanin supports you in the choice of solutions applicable to these processes.

- Accueil

- Our solutions

- Heat a solid

Heating solids: several possibilities are available to you

These illustrations are given as an example and only reflect some of the solutions that Acim Jouanin is able to offer.

Some materials have the particularity of forming solid clusters when they cool, creating a risk of clogging in the pipes of a process.

Our solutions make it possible to dry this material in contact with a heated surface, during its passage at a key moment in a process, for example, in a hopper .

Intended for heating and maintaining the temperature of solids and liquids, these thin resistors allow easy installation. Their watt density is limited to 0.8 W/cm² ( 180°C max ).

The plate heaters consist of an electrically insulated heating element ( mica 340°C or ceramic 650°C max .). They are generally fixed against a wall and emit heat by conduction or radiation.

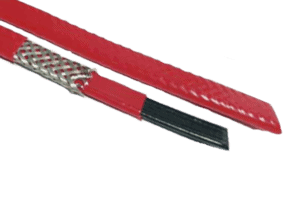

The self-regulating heating cables and constant power tracing, allow the heating of surfaces (cylindrical and flat) up to 120 °C. For higher temperatures, cables with mineral insulation will be preferred.

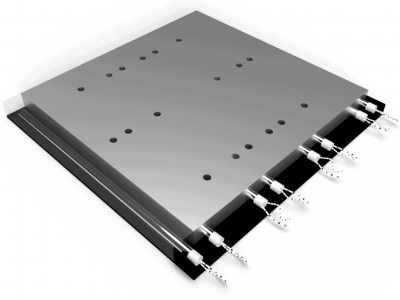

Acim Jouanin studies and designs custom made or standard heaters for heating plates , which can be used for molding rubber, plastic and composite parts.

These elements can be plated on the surface (flat heaters) or inserted in the heart of the plate (cartridge heaters) and associated with a temperature sensor.

The cartridge heaters are intended for heating at high temperatures (1000°C max) . Their small size makes it possible to concentrate a high power density (50 W/cm²) .

They are known for their thermal qualities and high conductivity. Present in injection and extrusion, they mainly equip molds and heating plates

Temperature measurement is essential to the proper functioning of your process.

We offer 3 sensor technologies: thermocouples, Pt100 sensors and infrared pyrometers .

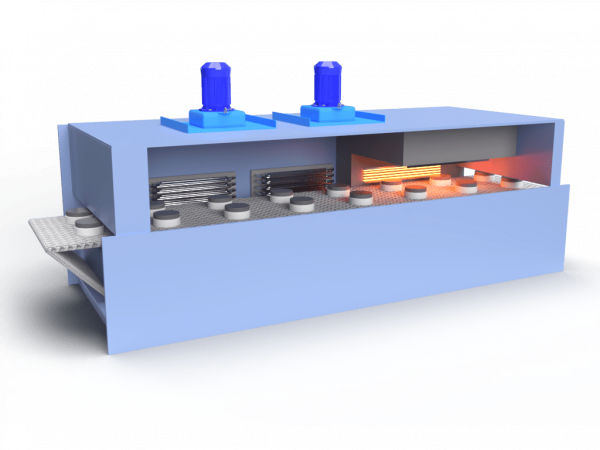

Air duct heaters are used for air treatment in drying and cooking processes. Inserted in ducts, they heat the circulating air.

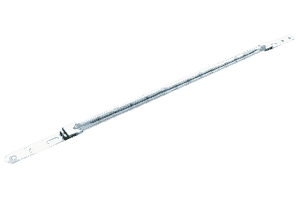

The infrared emitters and lamps allow the heating of the material, without contact while freeing itself from the atmosphere, thus limiting the thermal losses. Energy can be transmitted quickly, to targeted areas. The choice of technology used depends on the characteristics of the product to be treated.

There are three categories of infrared: short, medium and long.

Heating moving parts cannot be achieved by contact. It is therefore necessary to have an indirect heating element, making it possible to transfer the calories from a distance

Two technologies are possible: heating by hot air and by infrared.

From the single heating element to the complete drying tunnel , Acim Jouanin assists you in the definition and design of custom made assemblies respecting the needs and constraints of your processes.

Intended for heating liquids, gases or solids, tubular heaters, also called tubular elements, are present in many industrial applications, for heating and temperature maintenance.

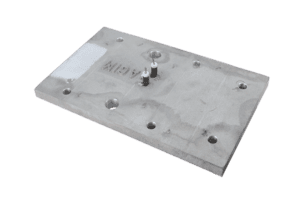

A cast heater is made of a tubular heater, embedded in an aluminum, cupro-aluminum (aluminum bronze) or brass alloy giving it excellent thermal conductivity.

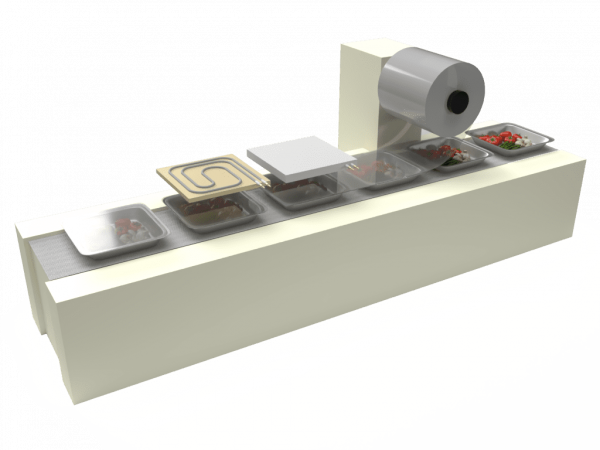

Heat sealing requires applying a precise temperature to the entire surface in contact with the protective film, in order to guarantee the quality of the seal and preserve the integrity of the contents.

Acim Jouanin offers solutions adapted to this type of process, in terms of power and heating speed.

In industry it is often necessary to preheat, reprocess, maintain temperature, harden parts or materials.

Acim Jouanin offers a range of heating tables , standard or custom made, dedicated to this type of application, integrating an electrical control panel.

Stand-alone or integrated into a cabinet, Acim Jouanin offers a wide range of temperature control products: sensors , regulators , actuators , electrical panels , etc.

Heating tables intended for maintaining the temperature or heating materials such as plastics and metals.

Mounted on a mechanically welded frame, the standard models operate up to 250°C . They are supplied with an electrical box and a PID control loop. Specific models on request.

Temperature management is an essential parameter in the success of a thermal process. If the heating element is essential, it is imperative to control it with a suitable regulation system.

This not only makes it possible to obtain the desired precision, but also to optimize the service life of the resistors.

In addition to our heating solutions , we can help you determine the most suitable model for your process.

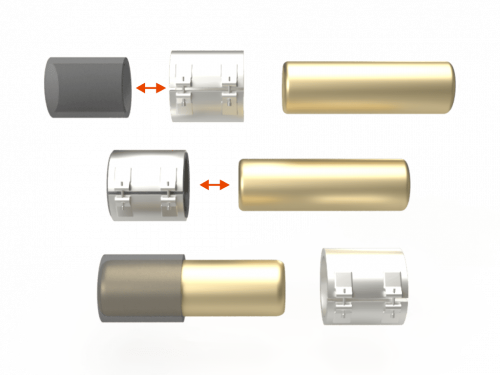

Beyond the heating of a sheath and its contents, bandheaters are also used for shrinking.

Playing on the phenomenon of expansion of metals, the outer element called hoop is heated in order to introduce the inner part, called hoop part and allow when the assembly cools, to make one and the other united.

Essential products in many industrial fields including the plastics industry, Acim Jouanin bandheatersare elements of various diameters and heights, intended for heating and maintaining the temperature of cylindrical parts (pipes, nozzles, sheaths, etc.).

You have a project ?