How to heat a liquid?

The heating of a liquid depends on many parameters: characteristics, desired temperature, environment, etc.

The extent of our ranges of products allows heating adapted to the nature of the fluid, whether in circulation or in static baths . We are also able to offer specific heaters for heating drums .

With more than 80 years of experience, Acim Jouanin will assist you in choosing your solutions.

- Accueil

- Our solutions

- Heat a liquid

Heating of liquids: some examples

The choice of the type of heating elements will be determined by several parameters:

the size and nature of the container, the method of fixing the element, the characteristics of the liquid itself and the method of heating ( direct or indirect ).

These illustrations are given as an example and only reflect some of the solutions that Acim Jouanin is able to offer.

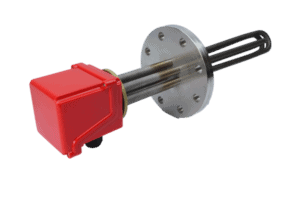

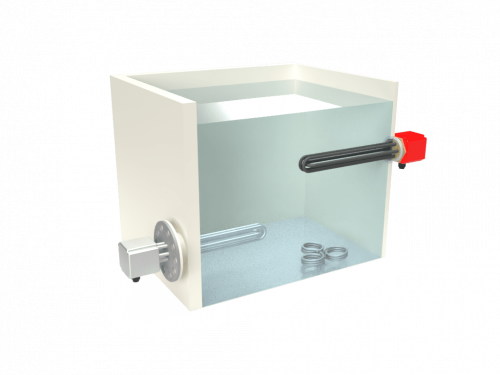

In the case of metal tanks containing non-aggressive products, heating can be carried out by direct contact with the fluid. The immersion heater can be fixed to the wall using a flange or a screw cap.

Fitted with 1 to several dozen heating elements, flange immersion heaters can generate power from a few hundred Watts to several hundred kilowatts.

Custom made, they can be fitted with standard (ANSI or ISO) or specific flanges (self-tightening, stamped sheet metal, etc.).

Generally consisting of 1 to 3 circuits welded or brazed on a threaded plug, immersion heaters with screw cap are commonly used for small and medium powers.

In addition to our standard ranges in GAS or ISO threaded caps, Acim Jouanin can offer you custom-made models adapted to your needs.

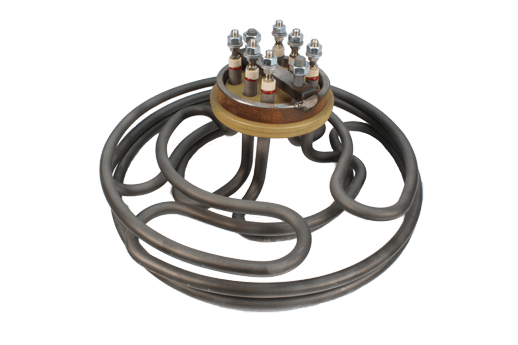

The immersion heaters for tank bottom are specially designed in the case where the walls of the tank do not allow drilling.

The tubulat heaters can be welded or brazed, on screw caps or flanges.

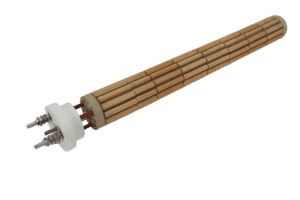

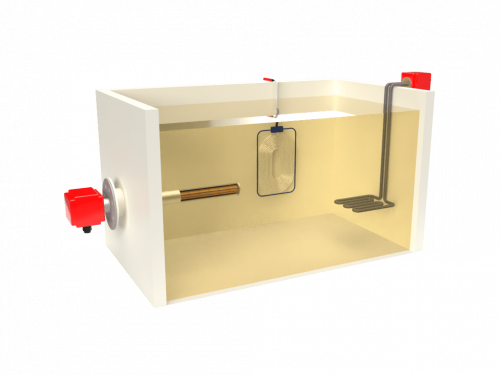

Liquids with aggressive or corrosive properties require suitable heating solution. Depending on the technology chosen, the immersion heater must have a reduced watt density, but also be protected by a sheath (such as for ceramic core heaters), a suitable coating (type Halar®), coated with a Teflon® sheath, … .

These immersion heaters have the advantage of being removable, allowing easy maintenance operations (no need to drain the tank, etc.)

Heaters made of a series of ceramic barrels, they are mainly used for heating liquids and gases. Their type of installation allows replacement without draining the tank .

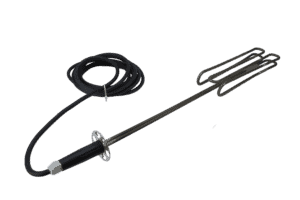

Removable immersion heaters are used when spot heating is required or when it is not possible to install a fixed immersion heater.

These devices are generally used in surface treatment baths and can be easily removed for tank maintenance.

Immersionheaters intended for heating corrosive baths , they can be placed either at the bottom of the tank or along the wall.

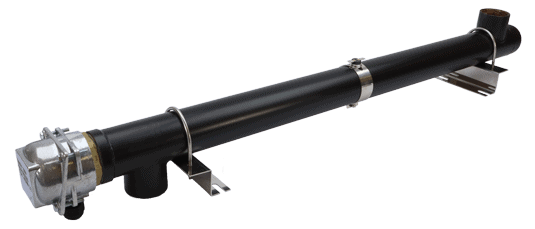

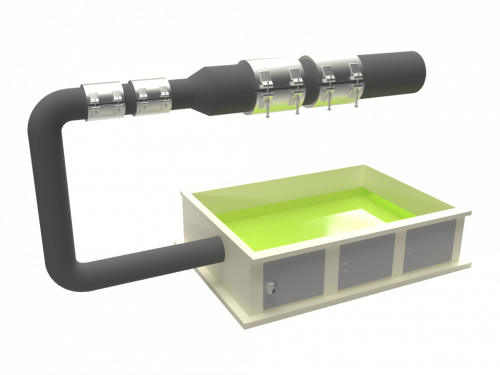

In-line circulation heaters are intended for heating circulating fluids . It is an immersion heater in a heating body where the fluids circulate and heat up.

Their applications are multiple, from the heating of food products, demineralized water, but also sensitive products such as fuel oil or oils for example.

Tracing involves wrapping a self- regulating or constant wattage heating tape around a pipe or enclosure.

Intended for heating and maintaining the temperature of solids and liquids, these very thin resistances make it possible to heat smooth surfaces, by conduction. This technology also allows the heating of curved surfaces, which cannot be achieved by metal resistors, such as mica plate heaters.

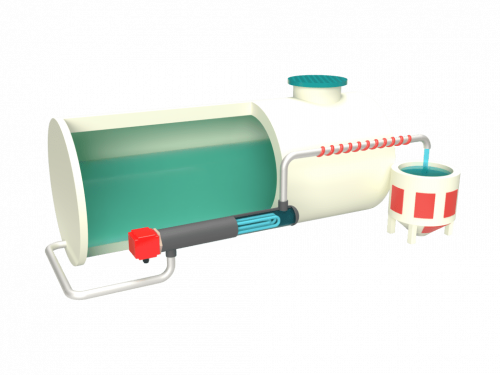

Associated with a pump, the circulating heater allows the indirect heating of a liquid contained in a tank, without any direct thermal intervention on the tank.

Another option lies in the possibility of heating the walls of the tank ( flexible heaters ) or the various inlet and outlet pipes ( tracing )

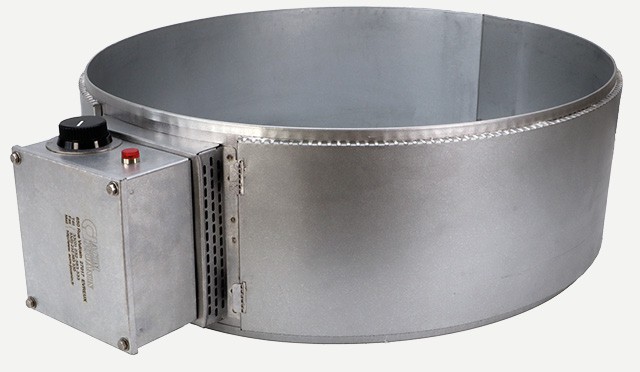

Essential products in the field of plastics processing, Acim Jouanin bandheaters are elements of various diameters and heights, intended for heating and maintaining the temperature of cylindrical parts (pipes, nozzles, sheaths, etc.).

The flat heaters consist of a heating element, electrically insulated by 2 mica layers. They are generally fixed against a wall and emit heat by conduction .

The heating of the liquid can also be carried out using bandheaters installed on the pipes or using flat mica heaters fixed to the walls of the tank.

Generally stored in drums, it is sometimes necessary to heat or maintain these liquids at temperature. Acim Jouanin has developed heating belts for these applications, in flexible or shielded versions.

Acim Jouanin offers a wide range of heating belts for metal drums or plastic drums, from 25 to 220 litres; solutions adapted to the material contained from low temperatures 0 to 90°C up to 300°C.

Particularly suitable for fragile products (low watt density), flexible silicone belts benefit from easier implementation than schielded models. However, their wattage is limited by their technology.

Allowing heating from the bottom of metal drums, the heating bases are excellent complements to the use of silicone or shielded heating belts.

For more specific applications ( plastic drums , IBC containers), Acim Jouanin offers belts or jackets adapted to the fragility of the contents (honey, spread, etc.) and containers (food, cosmetics, etc.).

Jackets designed for maintaining the temperature of products stored in standard IBC type storage containers.

Flexible heating belts are intended for heating and maintaining the temperature of plastic drums . The low watt density allows the heating of sensitive products (such as oils, grease, etc.) without degrading them.

You have a project ?